Making the best use of the mid-ship architecture of this new urban vehicle, the electric "i" or "i MiEV" then was announced in October 2006 as a research vehicle powered by a compact and lightweight motor and high-energy density lithium-ion batteries.

Less than 3 years later, once a thorough development process was completed accumulating over 500,000 km of testing, the car was launched in Japan as "i-MiEV" in July 2009 first with fleet customers. Books were then opened for private customers as well, the first deliveries to this second wave of Japanese clients taking place from April 2010.

The next commercial step starts today in Paris, prior to a start of production at MMC's Mizushima plant in October. Deliveries to European customers will then start in 14 selected markets from December 2010, depending country by country.

40 years of EV know-how at Mitsubishi

When announced as an EV research vehicle back in October 2006, the then non-hyphened "i MiEV" was the outcome of forty years of research and development at Mitsubishi in the area of electric powertrain.

As a reminder, work on the development and production of EVs started at Mitsubishi in October 1966, when Mitsubishi Heavy Industries Ltd (In 1970, the automobile division of Mitsubishi Heavy Industries Ltd. was spun off to become today's Mitsubishi Motors Corporation) was commissioned by Tokyo Electric Power Company (TEPCO) to build EV prototypes and conduct testing programs using improved battery technology: an inaugural EV program that was followed by several others, all laying the foundations for today's i-MiEV production car.

Mitsubishi Motors was also one of the first auto manufacturers to recognize the superiority of the lithium-ion battery over lead-acid batteries in terms of energy and output densities as demonstrated through the development in 1994 of the Chariot HEV plug-in hybrid, itself followed by various and successive testing programs to seek further improvements in performance, safety, reliability and durability.

Over 500,000 km of thorough testing

With the intention of moving the then "i MiEV" into commercial production Mitsubishi Motors carried out a number of in-house testing programs where the car sailed through, including extensive poor surface track, durability and reliability and crashworthiness.

In parallel, Mitsubishi i-MiEV went through a process of acquiring data through extensive fleet testing under a variety of climatic and real driving conditions. As an example, in Japan, a year-long joint proving program with 7 Japanese power companies using 37 development cars was carried out, covering a total of 300,000 km of testing and everyday commercial use.

The same process was engaged outside of Japan as well. In the case of Europe, 11 cars were used for a further 200,000 km of testing in a joint effort among Mitsubishi Corporation, its MC Automobile (Europe) N.V. subsidiary, Mitsubishi Motors Corporation and Mitsubishi Motors Europe towards European customers, be they corporate or private.

Self (battery)-reliant

In a further step towards making electric vehicles a viable business proposition, on December 12, 2007 Mitsubishi Motors Corporation joined hands with GS Yuasa Corporation and Mitsubishi Corporation and set up "Lithium Energy Japan" (LEJ), to develop, manufacture and sell large-size lithium-ion cells.

Within the LEJ joint-venture each partner brought its own leading know-how:

- GS Yuasa possesses advanced technologies in large lithium-ion batteries and is striving to broaden their applications.

- Mitsubishi Corporation intends to enter the battery manufacturing business and aims to create other related businesses as well.

- Mitsubishi Motors Corporation - which had electric cars on the road in Japan as early as 1971 - is working to strengthen its prominent position in (proprietary) EV technology.

LEJ plans to ramp up production of lithium-ion cells for use in powering Mitsubishi i-MiEV, enough from a start during FY2009 at its new plant in Kusatsu City Shiga Prefecture - the world's first plant dedicated to the mass-production of lithium-ion batteries for EVs, and to increase production volume thereafter with appropriate capacity to accompany the sales development of MMC's EVs:

- 2,300 units (= equivalent of Mitsubishi i-MiEV traction battery packs) from June 2009,

- 4,500 units from June 2010,

- With the start of production at LEJ's Kyoto plant the figure should reach 11,000 units,

- Lastly, the Ritto plant should allow for a total of 50,000 units from December 2012.

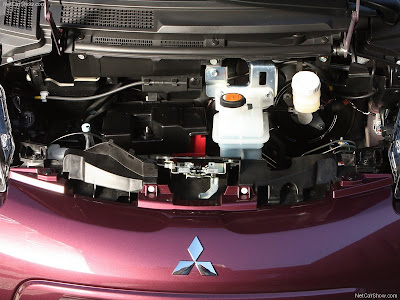

Space saving architecture

As a reminder, Mitsubishi i-MiEV is based on the "i" minicar platform where the rear-midship petrol engine and floor-mounted central fuel tank are replaced with a lithium-ion traction battery pack, the motor, the inverter and other EV components with only a modicum of modifications required to turn the petrol "i" into Mitsubishi i-MiEV.

This feature allowed the installation of a large capacity high density lithium-ion 88-cell traction battery pack within the long 2,550 mm wheelbase, i.e. without compromising seating for 4, whilst lowering the center of gravity of the car (by 65 mm vs. the petrol-powered "i") and protecting the batteries in case of a crash. Same for replacing i's 660 cc internal combustion engine with the 66.6ps/49 kW permanent magnet synchronous electric motor and ancillaries which preserved all 227 l of luggage space (extended to 860 l when both rear seats are folded down - VDA method).

High Capacity / Low costs

EV traction batteries must have high energy density. For that purpose, Mitsubishi i-MiEV utilizes LEJ's specifically developed high density lithium-ion battery pack, where each high capacity battery module can fit under the floor.

By design, Mitsubishi i-MiEV accepts 2 types of traction battery charging systems:

- The "Household Charging System" for anywhere near an ordinary electric outlet, via the household charger plug located on the right side of the vehicle: using European 230V 1 phase (16A) current, Mitsubishi i-MiEV can be re-charged in 6 hours from "Low Energy" warning. (Actual charging times may vary depending on such factors as air temperature and power source status).

- The "Quick Charger System" for speedy charging - where utilities, power companies, municipalities or corporations have installed quick chargers. There, Mitsubishi i-MiEV can be connected via the Quick Charger plug located on the left side of the vehicle: using the three-phase 200V 50 kW Quick Charge System, the car can be recharged from zero to 80% of its total charge in about 30 minutes (Actual charging times may vary depending on such factors as air temperature and power source status).

Motor (power unit)

Mitsubishi i-MiEV uses a high-efficiency compact and lightweight permanent magnet synchronous electric motor specially developed for the vehicle.

This unit generates maximum torque from low engine speeds (180 Nm - 0 to 2,000 rpm) to deliver powerful response (66.6ps/49 kW) and a seamless driving experience. When the vehicle slows down the regenerative braking system causes the motor to operate as a generator, the energy recovered being stored in the drive battery.

Transmission

Mitsubishi i-MiEV uses a lightweight and compact single-speed reduction gear transmission, exploiting the high low-end torque inherent to the electric motor and eliminating the need for complex gear shifting mechanisms as found in internal combustion engine powered vehicles.

On-board charger

Mitsubishi i-MiEV comes with a compact, lightweight on-board charger that allows the traction battery to be charged using a domestic AC line (voltage depends on the country).

DC/DC converter

The DC/DC converter is used to charge the 12-volt auxiliary battery and power electrical equipment. It is integrated with the on-board charger in a single unit to reduce size and weight.

Inverter

Mitsubishi i-MiEV 's motor is driven by an alternating current. The inverter converts high-voltage direct current from the traction battery to alternating current and supplies motor with the power required to drive the vehicle.

"MiEV OS" operating system

In this respect, Mitsubishi's "MiEV OS" (or "MiEV Operating System") - an advanced integrated vehicle management system into which the company has poured its wealth of know-how gained from decades of electric vehicle R&D - has provided the kind of high performance and reliability that befits a new-generation EV. "MiEV OS" has been awarded "2009 Japan Automotive Hall of Fame Car Technology of the Year" by the Japan Automotive Hall of Fame, a non-profit organization.

"MiEV OS" gathers data and information from all the major EV components to provide integrated management of the car's performance. This advanced management system constantly monitors battery status and the energy recovered from the regenerative brakes while regulating output to ensure smooth and powerful acceleration from a full stop. As a result the system optimizes and minimizes energy consumption to deliver the most appropriate actual on-road performance.

Living

Meant to be driven and used just as "normally" as a traditional ICE-powered car, Mitsubishi i-MiEV is a compact runabout which seats 4 within a short 3,475 m footprint, with the added bonus of 4 large doors, a real trunk (227 l of luggage space - extended to 860 l when both rear seats are folded down - VDA method) and a tight 4.5 m turning radius

Driving

In addition, Mitsubishi's i-MiEV adds range (150 km - "New European Driving Cycle "protocol), real life performance (top speed governed at 130 km/h, swift accelerations thanks to the 180 Nm of torque available from standing start), ultra-low well-to-wheel emissions, superior quietness and low level of vibrations to its potential customers.

When driving, the man-machine interface is materialized through two devices:

- Combination meter instrument cluster: It includes 1) an energy usage indicator that presents a visual display of power consumption and energy recovery status, 2) an energy level gauge that indicates how much remaining power there is left in the traction battery, and 3) a cruising range indicator that displays an estimate of how far the vehicle can be driven on the basis of average power consumption over the last few kilometers.

- Shift selector: Similar to the one of a traditional automatic gearbox, to accentuate the "regular car" feeling, it offers the usual P (Parking), R (Reverse), N (Neutral) and D (Drive) normally found with an A/T.

In addition, Mitsubishi i-MiEV also features two specific positions:

- B (Brake) which Increases the regenerative brake bias (for downhill driving).

- C (Comfort) which reduces the regenerative brake bias (for suburban driving).

Safety

As with all MMC vehicles, i-MiEV has been designed with a high standard of active & passive safety, including the specifics of its powertrain:

- i-MiEV features MMC's patented "RISE" design meant to integrate and interconnect structural elements for an active protection of the passengers during an accident. This design brings dramatic advances in multi-directional impact safety performance, dispersing energy loads during front, side and rear crashes and controlling distortion.

- The high voltage system traction battery pack is located inside the body frame - itself within the wheelbase - and is further protected by a well-crib frame against damage from any direction of impact.

- The rear combination lamps use fast-illuminating LED emitters for the tail and stop lamps, making these lamps more instantly visible to following vehicles while also cutting power consumption.

- Further standard safety measures include 6 airbags (driver + passenger + 2 x side + 2 x curtain) as well as Active Stability Control.

Cost of ownership

Translating the EV experience in financial terms, Mitsubishi i-MiEV's energy costs are minimal. In Europe and taking France as an example, a complete charge costs about € 2,00: just as low as the overall running costs of the vehicle, EVs being freed from the maintenance constrains of internal combustion engines and their transmission system.

Furthermore, Mitsubishi Motors plans to set the price (car + traction batteries) of the European-spec i-MiEV to around €33,000 - €35,000 (or equivalent) so that the final cost to the customer after government incentives (where applicable) remains under €30,000 (or equivalent) in a majority of the countries it is to be sold in.

Last but not least, MMC will offer a specific 5 year - 100,000 km warranty on all EV components.

From Japan to Europe

Whilst essentially the same car as the Mitsubishi i-MiEV sold in Japan since the summer of 2009, the EU-spec. version has been further developed to add a left-hand-drive version for continental markets and to comply with local regulations, including:

- Larger front bumper & newly-designed rear bumper,

- New lightweight aluminum wheels,

- Rear fog lamp,

- Larger outside rear view mirror,

- Immobilizer,

- ISO-FIX child seat anchors,

- 9-inch brake booster,

- Active Stability Control (ASC),

- Side & curtain airbags,

- Large head restraints,

- Seat belt warning lamp,

- Day-time running lights,

- Specific left-hand drive developments (dashboard, wash-wipe & HVAC systems, etc,…)